1. Energy Efficiency

Air-cooled evaporators are increasingly becoming the go-to choice for HVAC systems due to their superior energy efficiency. Unlike traditional water-cooled systems, which rely on large cooling towers and water treatment mechanisms, air-cooled evaporators use the ambient air surrounding the system to dissipate heat from the refrigerant. This approach significantly reduces energy consumption, making them a more sustainable and cost-effective option in the long run.

How It Works

In an air-cooled evaporator, the heat transfer process involves the refrigerant circulating through the evaporator coil, where it absorbs heat from the air inside the system. This heated refrigerant then travels to the condenser, where it releases the heat to the ambient air outside. The heat exchange is accomplished by fans that blow air over the coils to ensure optimal heat removal.

Reduced Energy Costs

Since the system does not require additional energy for water circulation and treatment, air-cooled evaporators can operate more efficiently. The energy used by air-cooled systems is largely confined to the fans that circulate air over the evaporator coils, which is typically much less than the energy consumed by water pumps, cooling towers, and water treatment systems in water-cooled units.

Advanced Control Systems

Modern air-cooled evaporators are equipped with advanced control systems that enable energy-saving features such as variable speed fans and smart thermostats. These systems allow the evaporator to adjust its performance based on environmental conditions, such as outdoor air temperature, thereby improving overall efficiency. The result is that air-cooled evaporators can work at optimal capacity without over-consuming energy, especially during times when cooling demand is low.

2. Lower Initial Installation Cost

The initial cost of installing an air-cooled evaporator system is generally lower than that of a water-cooled system. This cost-effectiveness makes air-cooled systems an attractive option for both residential and commercial HVAC installations, especially in regions where water resources are limited or expensive.

Simpler Installation Process

Air-cooled evaporators are relatively easy to install because they do not require complex plumbing systems or cooling towers. Water-cooled systems, on the other hand, require the installation of large cooling towers, complex water pipelines, and additional components such as water treatment systems to prevent scaling and corrosion. The lack of these requirements significantly reduces the upfront installation costs of air-cooled systems.

Minimal Site Preparation

Another advantage of air-cooled evaporators is that they require less site preparation. Water-cooled systems often need specialized areas for water tanks, cooling towers, and additional plumbing, which can add significant costs to the installation process. Air-cooled systems are compact and can be installed in existing spaces without the need for major modifications.

Lower Capital Investment

When comparing the capital investment needed for both types of systems, air-cooled evaporators generally provide a more budget-friendly option. This is especially important for small businesses or residential properties that may not have the financial resources for large-scale water-cooled installations.

3. Reduced Maintenance and Operational Costs

One of the significant benefits of air-cooled evaporators is their low maintenance requirements. Traditional water-cooled systems are prone to issues such as scaling, corrosion, and bacterial growth, which can lead to costly repairs and system failures. Air-cooled systems, on the other hand, are more straightforward to maintain and have fewer issues related to water quality.

Less Frequent Maintenance

Air-cooled evaporators generally require less frequent and less intensive maintenance than their water-cooled counterparts. The primary maintenance tasks involve cleaning air filters, checking fan performance, and inspecting the evaporator coils for dust and debris. In comparison, water-cooled systems need constant water treatment, cleaning of cooling towers, and regular inspection of water pipes to ensure that there is no scaling or biological growth.

No Water Treatment

Air-cooled systems do not require water treatment chemicals to prevent scaling, algae growth, or corrosion, which are common problems in water-cooled systems. This absence of water treatment simplifies maintenance and significantly reduces costs associated with purchasing and handling chemicals.

Longevity and Durability

The simplicity of air-cooled evaporators translates into a longer lifespan, as there are fewer components prone to wear and tear. The absence of water-related issues such as corrosion or scaling further contributes to the system’s durability, reducing the frequency and cost of repairs.

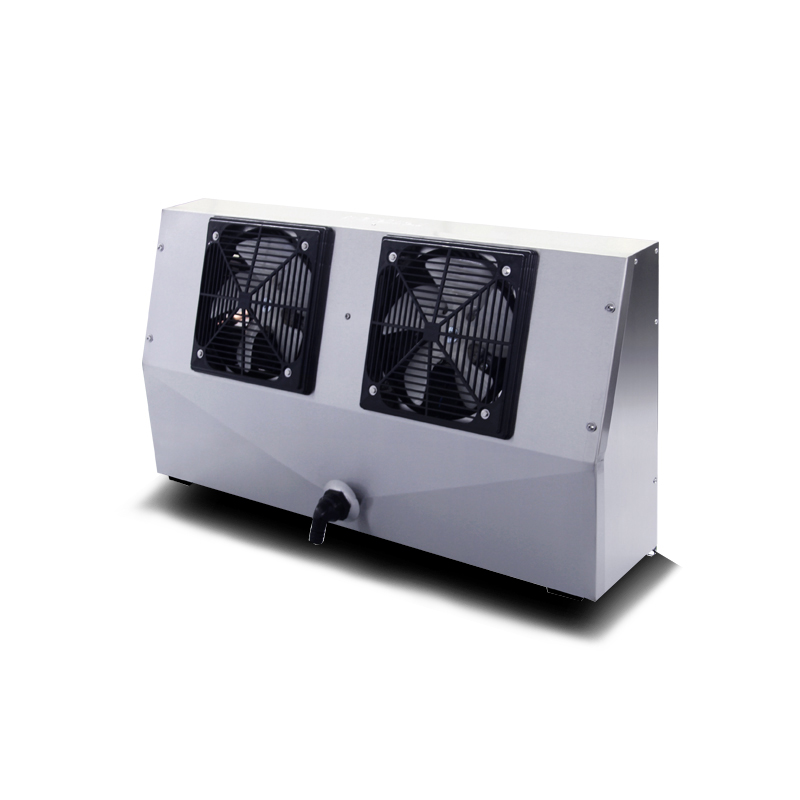

4. Compact and Flexible Design

Air-cooled evaporators are known for their compact and versatile design, which allows them to be installed in a wide range of environments. Whether in residential spaces, commercial buildings, or industrial facilities, air-cooled evaporators offer flexibility in terms of design and installation.

Space-Saving Features

Air-cooled systems are typically more compact than water-cooled systems. This makes them ideal for buildings or locations where space is limited. They can be easily integrated into existing HVAC systems or retrofitted into older buildings without requiring significant modifications. Their small size also makes them suitable for rooftop installations, saving valuable indoor space.

Installation in Various Environments

Air-cooled evaporators can be installed in various environments, from dense urban settings to remote locations where water supply may be inconsistent or unavailable. Their flexibility makes them an attractive choice for businesses that need reliable cooling but may not have access to traditional water-cooled infrastructure.

Design Customization

In many cases, air-cooled evaporators can be customized to fit specific cooling needs. They can be adapted to different building layouts and adjusted for varying airflows, making them suitable for both new construction and retrofit applications.

5. Environmental Benefits

In today’s world, sustainability is a key consideration in the design of HVAC systems. Air-cooled evaporators offer several environmental benefits that make them a better option when compared to traditional water-cooled systems, particularly in water-scarce regions.

Water Conservation

One of the most significant environmental benefits of air-cooled evaporators is their ability to conserve water. Water-cooled systems require large quantities of water to operate efficiently, and in many areas, this water must be treated before use. Air-cooled evaporators eliminate the need for water consumption, making them an environmentally friendly choice in areas where water resources are limited.

Use of Eco-Friendly Refrigerants

Many modern air-cooled evaporators utilize eco-friendly refrigerants that have a low global warming potential (GWP) and ozone depletion potential (ODP). By using refrigerants that have minimal environmental impact, air-cooled systems help reduce the overall carbon footprint of a building or facility.

Lower Carbon Footprint

The reduction in water consumption, energy efficiency, and the use of environmentally friendly refrigerants contribute to a lower carbon footprint. Air-cooled systems are therefore an excellent choice for companies looking to enhance their sustainability credentials and meet stringent environmental regulations.

6. Improved Reliability

Air-cooled evaporators are known for their reliability in operation, which is a critical factor for HVAC systems, especially in commercial and industrial environments where downtime can lead to significant losses.

Fewer Points of Failure

Air-cooled evaporators have fewer points of failure than water-cooled systems. Water-cooled systems rely on pumps, water treatment systems, and cooling towers, all of which have the potential to fail, leading to system downtime and costly repairs. In contrast, air-cooled evaporators have a simpler design, with fewer moving parts and components that are prone to failure.

Consistency in Performance

Because air-cooled systems do not rely on water quality, they can maintain consistent performance over time. This makes them more dependable, especially in harsh environments where water quality might fluctuate, affecting the performance of water-cooled systems.

Less Need for Emergency Repairs

Due to their simple design and fewer components, air-cooled evaporators require fewer emergency repairs, leading to more reliable operation. This can be especially beneficial for businesses that need continuous cooling, such as in food storage or pharmaceuticals.

7. Quicker Response Time

The quick response time of air-cooled evaporators makes them an ideal choice for applications that require rapid temperature adjustments, such as in industrial cooling or temperature-sensitive storage.

Rapid Cooling

Air-cooled evaporators can adjust quickly to changes in ambient temperature, allowing them to start cooling immediately once the need arises. This is particularly useful in environments where temperature control is critical, such as data centers, food processing facilities, and medical refrigeration.

Faster Recovery

In case of a cooling load fluctuation, air-cooled evaporators recover much faster than traditional water-cooled systems, ensuring that the environment remains within the desired temperature range without significant delays.

Flexible Temperature Control

These systems can be adjusted quickly based on varying cooling demands, making them suitable for environments with frequent or unpredictable temperature changes. This flexibility enhances their overall efficiency and performance.

8. Adaptability to Varying Environmental Conditions

Air-cooled evaporators are designed to operate efficiently in a wide range of environmental conditions, making them suitable for use in both hot and cold climates.

Effective in Hot Climates

In regions with hot temperatures, air-cooled evaporators can still perform effectively. Unlike water-cooled systems, which may struggle with heat rejection during peak summer months, air-cooled systems use ambient air to dissipate heat, ensuring reliable performance even in extreme conditions.

Cold Weather Performance

Even in colder climates, air-cooled evaporators can be adjusted to operate efficiently by utilizing defrost cycles, which help maintain optimal performance. This adaptability ensures that these systems remain useful across different environmental conditions.

9. Reduced Water Treatment Needs

Water-cooled systems require significant water treatment to prevent scaling, corrosion, and bacterial growth. Air-cooled systems eliminate these issues entirely, further reducing operational costs.

No Chemical Use

Since air-cooled evaporators do not rely on water, there is no need for chemicals to treat the water, saving on chemical costs and reducing environmental impact. This makes air-cooled systems

not only cost-effective but also eco-friendly.

Simpler Maintenance

With fewer components that require regular upkeep, air-cooled evaporators are easier and less costly to maintain, resulting in reduced service expenses over time.

10. Easy Integration with Smart Technologies

Air-cooled evaporators are increasingly being integrated with advanced smart technologies to improve efficiency and performance.

Smart Thermostats and Sensors

Many modern air-cooled systems are compatible with smart thermostats and sensors, allowing for remote monitoring and control. This integration allows operators to track performance, optimize energy use, and make real-time adjustments based on changing conditions.

Automated Maintenance Alerts

Air-cooled systems can be equipped with sensors that provide early warning alerts when maintenance is needed, reducing downtime and preventing costly repairs. Automated diagnostics can identify potential problems before they become major issues, ensuring smooth operation.

Building Management Systems (BMS)

Integration with Building Management Systems (BMS) allows for centralized control and monitoring of HVAC operations. This gives building managers full visibility into the system’s performance and energy consumption, making it easier to optimize usage and reduce waste.

English

English عربى

عربى Français

Français русский

русский Español

Español 中文简体

中文简体